|

| May 08, 2018 | Volume 14 Issue 17 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Universal Robots' cobots show off new packaging skills at NPE2018 plastics show

Collaborative robots are front and center in many new advanced manufacturing methods for composite part fabrication, blow molding, and high-mix/low-volume production. A new exhibitor at NPE -- the big plastics show at the Orange County Convention Center in Orlando, FL (May 7-11) -- is Universal Robots (UR), the company that pioneered the cobot and continues to be a market leader of the user-friendly robot arms that can work right alongside employees.

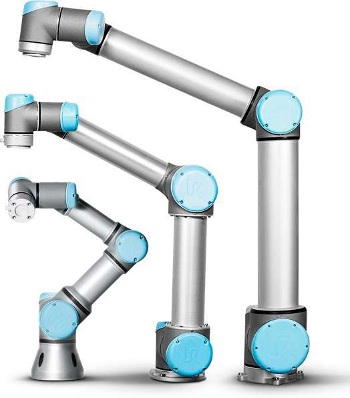

Universal Robots was co-founded in 2005 by the company's CTO, Esben Østergaard, who wanted to make robot technology accessible to all by developing small, user-friendly, reasonably priced, flexible industrial robots that are safe to work with. Since the first collaborative robot (cobot) was launched in 2008, the company has experienced considerable growth with the user-friendly cobot, which is now sold worldwide.

On display in the UR booth S27189 is the new Kanga Poucher from RND Automation & Engineering. Kanga is a vertical form/fill/seal pouching system that forms four-sided pouches for the medical device, pharmaceutical, and durable goods industries. The system integrates with a UR cobot, loading products into the pouches before the fourth, "top" seal is made after the product is indexed through the sealing gasket.

"Collaborative robots from Universal Robots reduce or eliminate the need for guarding, which means a significantly reduced footprint," says Sean Dotson, president and CEO, RND Automation & Engineering. "The fully customizable robots fill our customers' unique packaging needs. They also stop safely upon operator contact and can be moved with minimal force."

Also featured at Universal Robots' NPE booth is the Bulk Box Loader from Dyco, another system utilizing the small footprint and safety benefits of UR cobots. "We are getting a lot of requests from our customers to integrate Universal Robots throughout the blow molding process. End-of-line packaging is just one example of their numerous applications," says Mark Lovelace, sales manager with Dyco, a company that also offers a tray loading/palletizing system with UR cobots. "We selected UR for their robustness and design for use in industrial applications vs. other collaborative robots."

The integrated safety features of the UR cobots enables Dyco to offer continuous operation. The box loader cell includes two stations: while one box is being exchanged by an operator, the other box is being loaded by the robots. The system, shown loading plastic bottles at NPE, is designed for easy setup on a self-contained plate that can be redeployed between multiple blow molding production lines running different bottle and box sizes. The bulk box loader is a fully automated system controlled from the UR interface and a few push buttons.

Brian Dillman, area sales manager for Universal Robots, says, "It's great to see the industry now demanding UR robots for versatile application needs. Our product is uniquely positioned to address the pain points of the plastics manufacturers such as tightening labor markets, rapidly changing production lines, and the need to constantly lower overhead costs."

UR robots are also being exhibited in the following NPE booths:

Cold Jet: Booth W483

Cold Jet is a global leader that specializes in innovative dry ice cleaning solutions that improve manufacturing processes. At NPE, the company will be demonstrating a better way to clean molded parts prior to painting.

The Cold Jet Combi 120H system is a waterless system that incorporates JIT dry ice production and an integrated blasting system. Cold Jet systems safely and gently remove a variety of contaminants from the molded parts using dry ice, eliminating the need for aqueous and solvent-based cleaning methods and the associated large-parts drying ovens. The demo system incorporates a UR10 collaborative robot cleaning automotive mirrors.

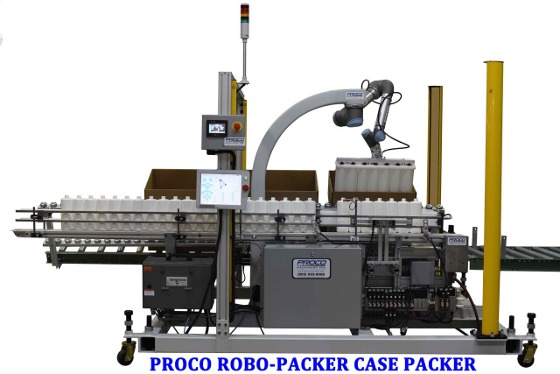

Proco Machinery: Booth W983

A leading manufacturer of automation systems for the blow molding industry, Proco will showcase the new collaborative robotic Half-Cube Palletizer system and the Robo-Packer. The Half-Cube Palletizer delivers a major cost reduction versus conventional automation, as the system automatically palletizes blow molded containers with minimal operator involvement; only manual operations occur when an operator places the trays in the magazine. The system quickly adapts to a variety of packaging configurations (i.e., all necks up or all necks down).

The palletizer is an integrated module supplied with the UR robot arm, infeed conveyor, pallet lift magazine, and slip sheet/tray pick on a common sub-frame fitted with leveling pads and castor wheels. The Robo-Packer is a breakthrough collaborative robotic automation system that works interactively with co-workers, requires no special guarding, and needs minimal training for teaching new tasks. The system is supplied with any of the three UR robot models, depending on the application, and comes at a cost that is 50 percent less than conventional automation solutions.

Source: Universal Robots

Published May 2018

Rate this article

View our terms of use and privacy policy